Let's Get Straight To The Point

Reverse logistics, the process of handling returns, repairs, recycling, and disposal of products, is becoming increasingly crucial in the freight industry due to the rise of e-commerce and shifting customer expectations. With e-commerce returns often exceeding 30%, companies need efficient reverse logistics systems to manage the flow of returned goods, reduce operational costs, and enhance customer satisfaction.

It also provides opportunities for sustainability and revenue recovery through refurbishing or reselling returned items. Key challenges include managing return complexities, lack of infrastructure for reverse flows, and high costs.

However, new technologies like AI, automation, and blockchain are helping businesses improve efficiency, integrate reverse logistics with the supply chain and optimise operations for future growth.

With Cario Freight Management Solutions, doing return consignments or even controlled returns is simpler, giving businesses the flexibility and visibility they need to manage complex return flows effectively.

What is Reverse Logistics

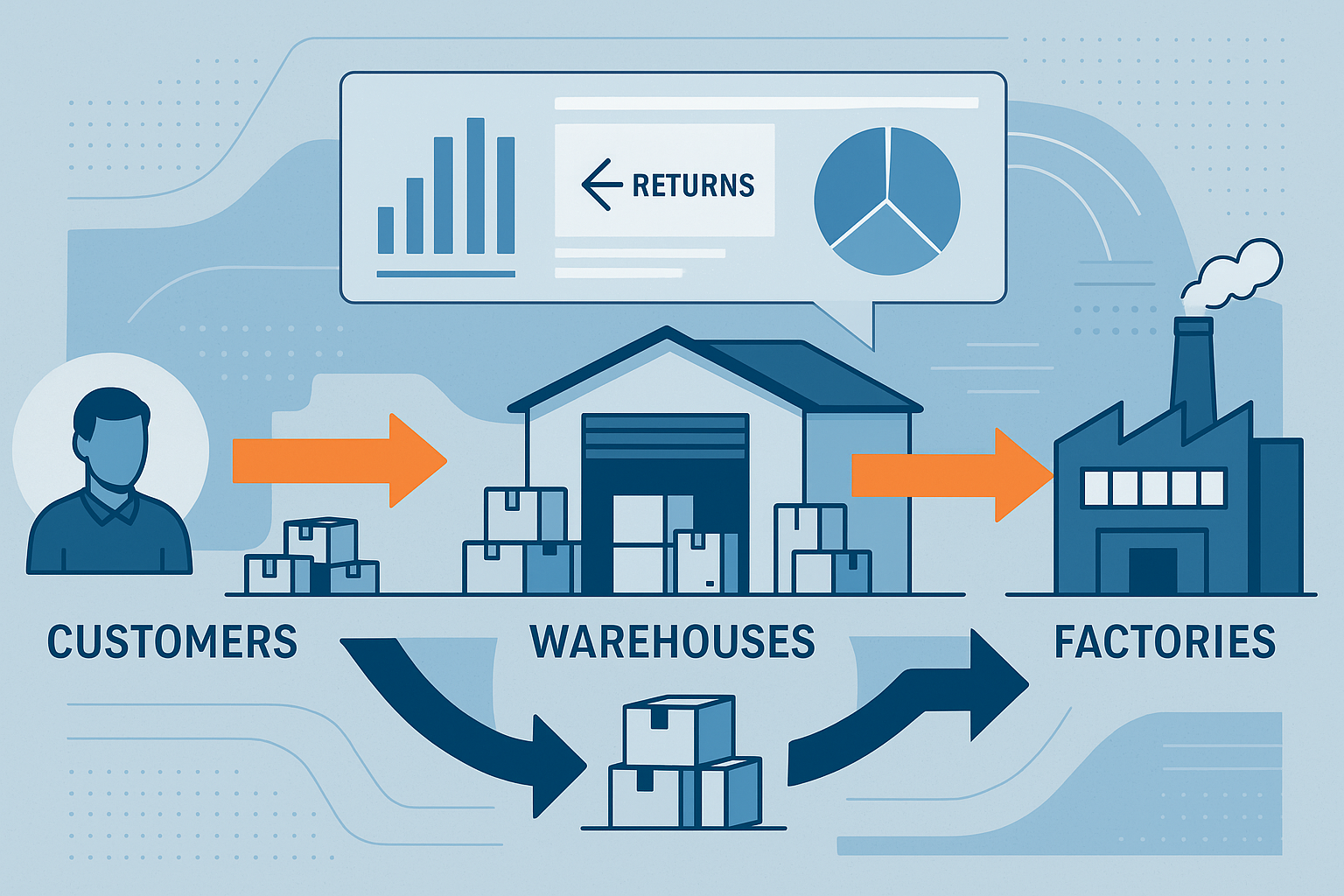

Before diving into its growing importance, it’s essential to first define reverse logistics. Reverse logistics refers to the process of moving goods from the end consumer back to the manufacturer or distributor. This can include the return of products, repair and refurbishment, recycling, or disposal of goods that are no longer needed or functional.

In traditional logistics, the focus is on moving products from suppliers to end consumers. However, reverse logistics works in the opposite direction, handling the flow of products back from consumers to businesses for a variety of purposes. As e-commerce continues to flourish, so does the need for efficient reverse logistics solutions.

What Makes Reverse Logistics Different From Forward Logistics?

While forward logistics deals with the transportation of goods from manufacturers or suppliers to customers, reverse logistics involves products going in the opposite direction. It covers all activities related to the return of goods, including:

Returns management: Handling product returns from customers, whether due to defects, dissatisfaction, or wrong orders.

Refurbishment and repairs: When products are returned, they may need to be repaired or refurbished before being sent back to the market or recycled.

Recycling and disposal: Some products may be too damaged to be resold, requiring proper disposal or recycling.

Reverse logistics requires different processes, technologies, and strategies than forward logistics. It typically involves more complexity, including managing customer expectations, reverse inventory handling, and processing returns quickly and efficiently.

The Rising Significance of Reverse Logistics in Freight

Increasing E-Commerce Returns

One of the main reasons reverse logistics is gaining attention is due to the rapid growth of e-commerce. As more consumers shop online, the volume of product returns is also rising sharply. According to recent reports, returns in e-commerce can be as high as 30%, compared to just 8-10% for traditional retail. This surge in returns is a major challenge for freight people who must efficiently manage these returns.

In the world of freight, returns can lead to significant inefficiencies if not managed properly. Traditional supply chains are set up for the forward movement of goods, not reverse flows. Hence, as e-commerce continues to expand, businesses must adopt more robust reverse logistics strategies to manage these returns effectively and reduce costs.

Customer Expectations For Easy Returns

Customers today expect easy and free returns, and this expectation has reshaped the landscape of freight and logistics. In fact, a study found that 67% of shoppers are more likely to buy from a retailer that offers free returns. This means that businesses need to prioritise the development of seamless reverse logistics operations to retain customer loyalty and enhance their brand image.

The pressure to offer smooth, hassle-free returns means that logistics providers, including those in freight, need to adjust their models to accommodate this growing trend. Companies with well-organized reverse logistics operations can create a competitive advantage by making returns easy and fast for consumers.

Cost Management And Efficiency Gains

Managing reverse logistics efficiently can help companies reduce operational costs and improve profitability. Handling returns involves a series of steps, including collection, inspection, sorting, restocking, and sometimes refurbishment. Without the proper systems in place, businesses can incur significant expenses due to wasted resources and inefficiencies.

By implementing reverse logistics best practices, freight companies can streamline these processes, making them more cost-effective. Technologies like automation, real-time tracking, and data analytics can enhance the reverse flow of goods, reducing overhead and improving resource utilisation.

Moreover, reverse logistics can help businesses recover value from returned products by refurbishing them, reselling them, or recycling valuable materials. These actions contribute to sustainability and can create additional revenue streams, thereby making reverse logistics an important aspect of modern freight operations.

The Key Benefits of Reverse Logistics in Freight

Improved Customer Satisfaction

As mentioned earlier, customers demand easy and hassle-free return processes. A well-managed reverse logistics system improves customer satisfaction by making returns quicker, easier, and more transparent. Whether it’s returning a defective product, exchanging an item, or simply changing an order, customers are more likely to return to businesses that offer a smooth returns experience.

For freight people, managing this aspect is crucial for maintaining strong customer relationships. Companies that fail to adapt to the demand for efficient returns may risk losing their competitive edge in the marketplace.

Increased Sustainability And Environmental Responsibility

Sustainability is another driving factor behind the importance of reverse logistics. With the increased focus on reducing waste and conserving resources, reverse logistics offers a way to minimise environmental impact. Companies that handle returns and product disposal responsibly can significantly reduce their carbon footprint by recycling products or parts.

The concept of the circular economy is at the heart of reverse logistics. This is where products are reused, refurbished, and resold, creating a sustainable supply chain. For freight people, this means adopting practices that prioritise not only operational efficiency but also environmental responsibility.

Revenue Recovery Through Refurbishing And Reselling

Another key benefit of reverse logistics is the potential to recover revenue from returned items. Many returned products are still in good condition or can be refurbished to sell again. By efficiently managing returned goods and finding new uses for them, businesses can recapture some of the losses incurred from returns.

For instance, electronic products, furniture, and high-value items may have a significant resale value after being refurbished. Freight companies can play a crucial role in managing this process by providing the necessary infrastructure to collect, inspect, and resell these products, allowing businesses to recover some of the financial losses from returns.

Key Challenges in Reverse Logistics

Despite its benefits, reverse logistics comes with several challenges that freight people must address. Understanding these obstacles is key to designing and implementing effective reverse logistics strategies.

Increased Complexity In Supply Chain Management

The complexity of reverse logistics often stems from the fact that products are not always returned in a standardised manner. Each return may vary depending on the product, condition, and reason for return. This variability makes it more difficult to manage returns in a way that is cost-effective and efficient.

Additionally, when returns involve a mix of products—such as electronics, clothing, and perishable goods—freight providers must ensure that the products are properly handled according to their unique requirements. This adds an extra layer of complexity to freight logistics, as different categories of products require different types of processing, storage, and handling.

Lack Of Infrastructure For Reverse Flows

Many logistics networks are optimised for forward flows, meaning that the infrastructure in place to handle outbound shipments might not be suited for returns. Proper infrastructure is essential for reverse logistics to run smoothly.

For example, warehouse facilities may need to be adapted to accommodate the influx of returned goods. Sorting systems, storage solutions, and transportation networks must be reengineered to handle returns efficiently. Without these specialised systems in place, the returns process can become cumbersome, leading to delays and increased costs.

Managing The Costs Of Returns

While reverse logistics can offer cost-saving benefits, it can also be costly if not managed effectively. The transportation of returns, inspection and refurbishment costs, and the labour involved in handling returns can quickly add up.

Many companies are still working on strategies to reduce the cost of reverse logistics while maintaining customer satisfaction. By leveraging technologies such as automation and AI-based systems, businesses can streamline their processes and reduce the overhead associated with returns.

How Reverse Logistics is Shaping the Future of Freight

The Role Of Technology In Reverse Logistics

Technology plays a pivotal role in shaping the future of reverse logistics. Innovations like artificial intelligence (AI), machine learning, automation, and blockchain are being incorporated into logistics systems to improve efficiency and transparency in returns management.

AI and machine learning, for example, can help predict return patterns based on customer behaviours, allowing companies to optimise their returns processes in advance. Automation, meanwhile, can streamline sorting and processing, while blockchain technology offers the potential to track returned goods securely and transparently.

For freight people, embracing new technologies is key to staying ahead of the curve in reverse logistics. These tools can help businesses reduce operational costs, improve accuracy, and speed up processing times.

Integration Of Reverse Logistics With The Supply Chain

As reverse logistics becomes an integral part of the overall supply chain, its integration with forward logistics is becoming increasingly important. Freight companies are now working to link reverse logistics with their broader supply chain management systems. By doing so, they can create a seamless flow of goods, minimise delays, and reduce inefficiencies.

This integrated approach not only streamlines the logistics process but also enhances visibility, allowing for better decision-making across the supply chain. It also provides businesses with a more comprehensive view of their entire inventory and product lifecycle, further optimising operations.

The Future Of Reverse Logistics In Freight

Looking ahead, reverse logistics is expected to grow even more significantly in the freight industry. As e-commerce continues to evolve, businesses will need to continue innovating to manage returns more effectively. By embracing new technologies, improving infrastructure, and refining their processes, freight companies can create a more efficient, sustainable, and profitable reverse logistics operation.

Conclusion

The growing importance of reverse logistics in freight cannot be overstated. As the demand for online shopping continues to rise and customer expectations evolve, the ability to manage returns efficiently has become a key factor in business success. Freight people must embrace new technologies, optimise their infrastructure, and develop strategies to handle reverse logistics in a way that enhances customer satisfaction, reduces costs, and supports sustainability.

By adopting forward-thinking approaches to reverse logistics, companies can not only stay competitive in an increasingly challenging market but also turn challenges into opportunities for growth and efficiency. As the logistics landscape continues to shift, reverse logistics will undoubtedly play a central role in shaping the future of the freight industry.

FAQs

Why Is Reverse Logistics Becoming More Important In Freight?

The rapid growth of e-commerce and increased customer expectations for easy and free returns are driving the need for efficient reverse logistics. As return rates grow, businesses must adapt their logistics operations to manage returns effectively and reduce costs.

What Challenges Does Reverse Logistics Face?

Reverse logistics presents challenges such as managing the complexity of returns (different products and conditions), lack of infrastructure designed for reverse flows, and high costs associated with returns handling, inspection, and refurbishing.

What Are The Benefits Of Reverse Logistics?

Key benefits include improved customer satisfaction through easy returns, increased sustainability by recycling and reusing products, and potential revenue recovery through refurbishing and reselling returned goods.

How Can Technology Help With Reverse Logistics?

Technologies like artificial intelligence (AI), automation, and blockchain are helping improve the efficiency, transparency, and speed of reverse logistics. AI can predict return patterns, automation can streamline sorting, and blockchain can enhance the tracking of returned goods.

How Does Reverse Logistics Impact Sustainability?

Reverse logistics plays a key role in sustainability by reducing waste and conserving resources through recycling, refurbishing, and reselling products. It supports the concept of a circular economy, where products are reused and their life cycles extended.