Enterprise Resource Planning (ERP) and Freight Management Systems (FMS) are foundational tools for managing modern business operations.

Their integration, often called ERP integrations, promises streamlined workflows, enhanced supply chain visibility, and increased operational efficiency.

However, successful integration requires careful planning, strategic execution, and adherence to best practices for integrating ERP with freight management systems.

This article provides a comprehensive guide to achieve seamless integration and reap its transformative benefits.

Let's Get Straight to the Point

Integrating Enterprise Resource Planning (ERP) with Freight Management Systems (FMS) enhances operational efficiency, supply chain visibility, and customer satisfaction.

This process involves thorough planning, selecting the right integration method, and focusing on data integrity, standardisation, and validation.

Benefits include streamlined logistics, real-time data sharing, cost savings, and better customer experiences through accurate shipment tracking and timely deliveries. Challenges like data silos and security are addressed with unified systems and robust governance.

Ongoing maintenance, user training, and a centralised repository ensure successful implementation and sustained performance, aligning the integration with business objectives and market demands.

Understanding ERP and Freight Management Systems

1. What is an ERP System?

An Enterprise Resource Planning (ERP) system is a robust solution for unifying and managing critical business functions on a single platform. By eliminating manual processes and fostering automation, ERP systems enhance efficiency in supply chain operations and other key areas.

Key features of an ERP system include:

Inventory management to track stock levels and demand patterns.

Customer relationship management (CRM) to track customer interactions and improve satisfaction.

Financial management to ensure accurate accounting and budgeting.

Human resources modules to streamline personnel administration.

Warehouse management system (WMS) to manage warehousing spaces and inventory processes.

A well-integrated ERP solution ensures data centralisation, enabling real-time data analysis and seamless communication between departments.

2. Freight Management Systems Overview

Freight Management Systems (FMS) are software solutions that streamline and optimise freight operations, including transportation management, freight auditing, and freight payment.

These systems help companies manage freight operations more efficiently, reduce costs, and improve customer satisfaction. By integrating FMS with ERP systems, businesses can gain a comprehensive view of the entire supply chain, from procurement to delivery.

This holistic approach ensures that all aspects of freight management are aligned with broader business processes, enhancing overall operational efficiency and customer satisfaction.

3. What is a Transportation Management System?

A Transportation Management System (TMS) focuses on optimising logistics and transportation workflows, and transportation management systems are crucial for managing the logistics of transporting goods. With functionalities like shipment tracking and transportation planning, TMS systems empower businesses to:

Enhance data accuracy in routing and scheduling.

Provide real-time data on shipment statuses.

Ensure timely deliveries by optimising carrier and route selection.

The integration of TMS with ERP enables organisations to align logistics with overall business objectives, bridging gaps between supply chain management and operational demands.

Benefits of Integration

1. Advantages of Integration

Integrating ERP and TMS through ERP integrations delivers measurable benefits across business operations:

Improved Efficiency: Automation eliminates manual data entry, saving time and reducing errors.

Enhanced Visibility: Real-time data sharing provides comprehensive insights into supply chain operations.

Cost Savings: Streamlined workflows reduce overhead costs, from inventory management to logistics.

This integration process fosters collaboration across departments, aligning functions such as warehouse management systems and logistics with overarching business needs.

2. Enhanced Customer Experience

Customer satisfaction is a priority for any business. With ERP-TMS integration, organisations can offer:

Shipment tracking and proactive updates on delivery statuses.

Accurate and timely deliveries to build trust.

Streamlined order processing to enhance service reliability.

These features translate to long-term customer satisfaction and loyalty, establishing a competitive edge in the market.

Pre-Integration Planning and Preparation

1. Assessment and Planning

Comprehensive planning is important before initiating integration. Key steps include:

Existing Systems Assessment: Evaluate the capabilities and limitations of current business processes and tools.

Business Needs Analysis: Identify gaps and potential workflow enhancements, such as financial data management or data security measures.

Stakeholder Engagement: To ensure a holistic integration strategy, stakeholders from departments like finance, logistics, and IT should be included.

This assessment lays the groundwork for a targeted, effective integration that aligns with the company’s long-term goals.

2. Choosing the Right Integration Method

Selecting the optimal integration method is essential for success. Options include:

Point-to-point integration: Direct connections between specific modules for focused functionality.

Middleware solutions: Centralised platforms for complex, multi-system integrations.

Scalable approaches that accommodate future business growth.

Carefully consider compatibility with existing systems, cost-effectiveness, and adaptability to data formats and workflows.

Integration Best Practices

1. Data Management

Effective data management ensures data integrity and supports seamless operations. Best practices include:

Data Standardisation: Align data formats across systems for uniformity.

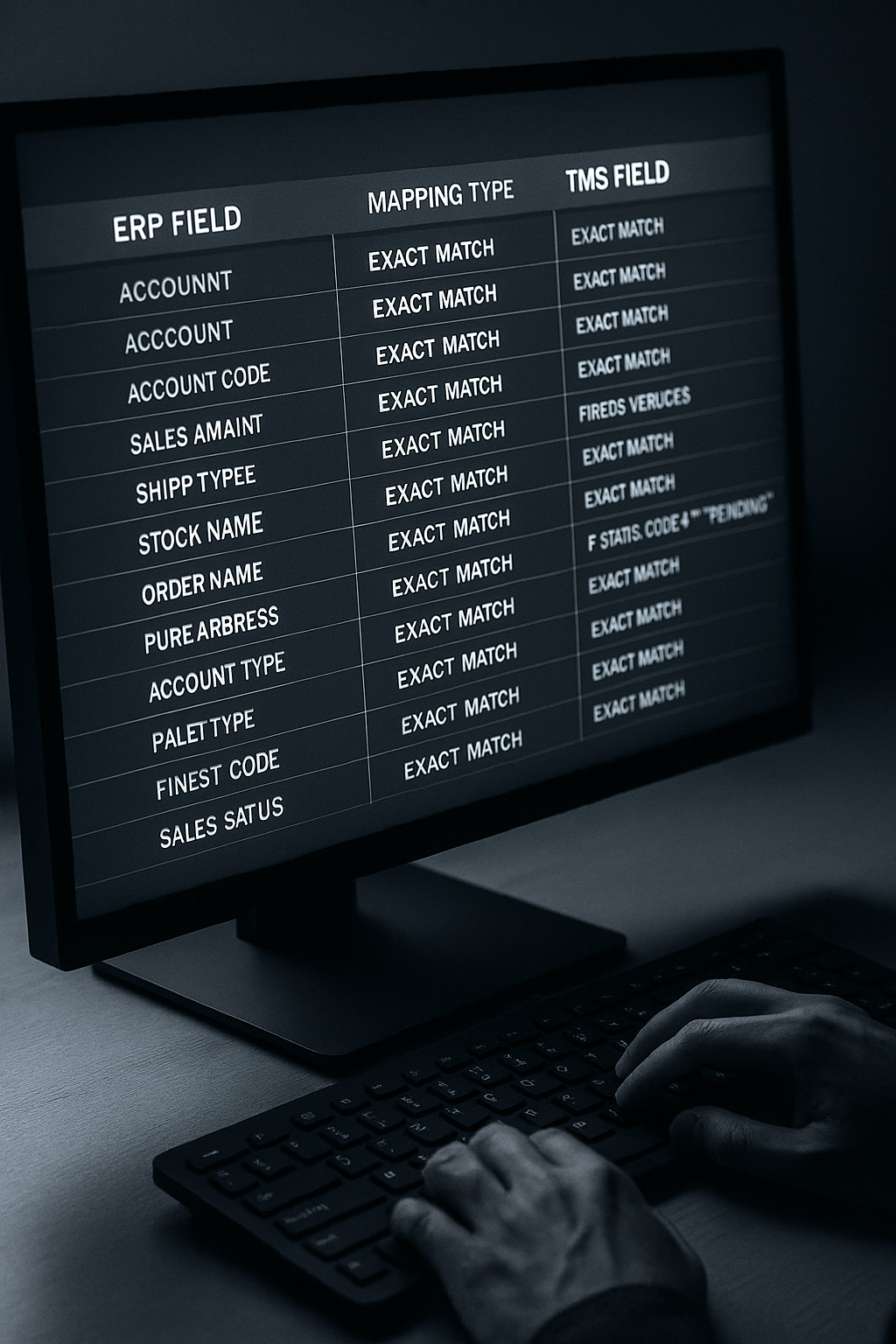

Data Mapping: Ensure consistent field mapping between ERP and TMS systems.

Data Validation: Verify accuracy during the integration process to prevent inconsistencies.

Strong data governance policies safeguard sensitive information, aligning with data protection regulations and minimising risks.

2. Data Standardisation and Mapping

Data standardisation and mapping are critical components of the ERP integration process. Data standardisation ensures that data formats and structures are consistent across all systems, while data mapping defines how data will be exchanged and transformed between systems.

This process ensures that data is accurate, complete, and consistent across all systems and can be easily exchanged and used by different departments and stakeholders.

By standardising and mapping data, businesses can achieve seamless data flow, reduce errors, and enhance the overall efficiency of their integrated systems.

3. Testing and Validation

Thorough testing is a non-negotiable step in successful integration. Prioritise the following:

Unit Testing: Validate individual system components before combining them.

System Performance Testing: Assess how the integrated system handles real-world scenarios, such as high-volume data exchange.

End-User Validation: Ensure the solution meets the needs of those who will use it daily.

This process helps detect and resolve issues before full deployment, ensuring smooth and reliable performance.

Ensuring Data Integrity and Security

Ensuring data integrity and security is a critical aspect of ERP integration. Data

integrity refers to data accuracy, completeness, and consistency, while data security refers to protecting data from unauthorised access, theft, or damage.

By prioritising these elements, businesses can maintain reliable and secure data, which is essential for informed decision-making and operational efficiency.

1. Data Validation and Verification

Data validation and verification involve checking data for accuracy, completeness, and consistency before entering it into the ERP system.

This process ensures that data is reliable and trustworthy and can be used to make informed business decisions. Data validation and verification can be performed manually or automatically using tools and software that check data against predefined rules and criteria.

By ensuring data accuracy at the outset, businesses can avoid costly errors and maintain high data quality throughout their operations.

2. Security Protocols and Access Control

Security protocols and access control are essential for protecting data from unauthorised access, theft, or damage.

Security protocols involve implementing measures such as encryption, firewalls, and intrusion detection systems to prevent unauthorised access to the ERP system. Access control involves defining who has access to the ERP system, what data they can access, and what actions they can perform.

This ensures that sensitive data is protected and that only authorised personnel can access and modify it. By implementing robust security measures, businesses can safeguard their data and maintain the integrity of their ERP systems.

Implementation and Maintenance

1. Implementation Roadmap

A structured roadmap is vital for a smooth transition to an integrated ERP system. Key phases include:

Planning and Preparation: Define clear milestones, resource allocation, and team responsibilities.

Testing and Validation: Reassess system readiness with rigorous testing protocols.

Training Programs: Develop comprehensive training materials tailored to different roles.

Go-Live Support: Provide immediate assistance during the early stages of implementation.

2. Ongoing Maintenance and Support

Post-implementation, regular maintenance ensures the system remains robust and effective. Focus areas include:

System Updates: Apply patches to address vulnerabilities and improve functionality.

Performance Monitoring: Continuously evaluate system efficiency and resolve issues promptly.

User Support: Offer accessible help desks and troubleshooting resources.

Proactive maintenance safeguards the company’s investment and ensures continued alignment with evolving business functions.

Change Management and Training

1. Providing Adequate Training to End Users

Training is pivotal to the success of ERP-TMS integration. Effective strategies include:

Role-specific training programs that address unique departmental needs.

Multiple training formats, such as video tutorials, hands-on sessions, and user manuals.

Periodic refresher courses to ensure sustained proficiency.

This approach empowers employees to adapt to the new system, minimising disruptions to business operations.

2. Maintaining a Central Repository

A centralised repository of integration resources is invaluable. Include:

Documentation on integration methods, system configurations, and workflows.

Training materials for easy access and reference.

Updates on changes to processes or tools.

This repository acts as a single source of truth, ensuring consistency and reducing confusion during and after the integration.

Key Challenges and Solutions

1. Addressing Data Silos

Data silos create inefficiencies by isolating critical information. Overcome this challenge by:

Implementing an integrated system to promote cross-departmental collaboration.

Automating data exchange processes for real-time access.

2. Ensuring Data Security

Protecting sensitive data is a critical aspect of integration. Key measures include:

Encrypting financial data and customer data.

Conducting regular security audits to identify and resolve vulnerabilities.

Complying with data protection regulations to maintain trust.

3. Streamlining Logistics Operations

Integration enables smoother logistics operations by connecting TMS and ERP functionalities through ERP integrations. Benefits include:

Enhanced coordination between warehouse management and transportation.

Better inventory visibility for real-time data insights.

Automated workflows that reduce delays and errors.

Practical Tips for Seamless Integration

Use trusted tools like Microsoft Dynamics for robust integration.

Ensure the solution aligns with current and future business objectives.

Regularly assess system performance to maintain peak efficiency.

Invest in ongoing support to address evolving needs and maintain a competitive edge.

Conclusion

Integrating ERP with Freight Management Systems is a transformative initiative that drives efficiency, visibility, and customer satisfaction.

By following these best practices for integrating ERP with freight management systems, organisations can:

Achieve seamless data flow and eliminate data silos.

Improve logistics and enhance supply chain visibility.

Ensure alignment with evolving business needs and market demands.

A structured approach guarantees the success of ERP-TMS integration, from meticulous planning to post-implementation support.

By prioritising data integrity, user training, and ongoing support, businesses can unlock the full potential of their enterprise resource planning (ERP) and freight management systems.

This integration streamlines operations and positions organisations for sustainable growth and success in a competitive landscape.

FAQs

1. Why is integrating ERP with Freight Management Systems important?

Integrating ERP with Freight Management Systems improves operational efficiency, streamlines logistics processes, and enhances supply chain visibility. It eliminates data silos and ensures seamless data exchange between systems.

2. What are the main challenges in ERP and FMS integration?

Key challenges include maintaining data integrity, addressing compatibility with existing systems, and ensuring data security. Proper planning, testing, and governance can help overcome these obstacles.

3. How does integration benefit customer satisfaction?

Integration enables real-time shipment tracking, accurate order processing, and timely deliveries. These features improve customer trust and loyalty by offering a better service experience.

4. What is the best approach for ERP-FMS integration?

The optimal integration method depends on your systems and business needs. Options like point-to-point integration or middleware solutions should align with scalability, cost, and data exchange requirements.

5. How can businesses ensure a successful integration?

Businesses should conduct thorough planning, rigorously test the systems, and provide user training. Ongoing support and regular updates are essential for maintaining system performance and ensuring long-term success.